Understanding the Aluminum Casting Process: A Modern Perspective

Wiki Article

Exploring the Art of Metal Casting: Strategies and Applications in Modern Foundries

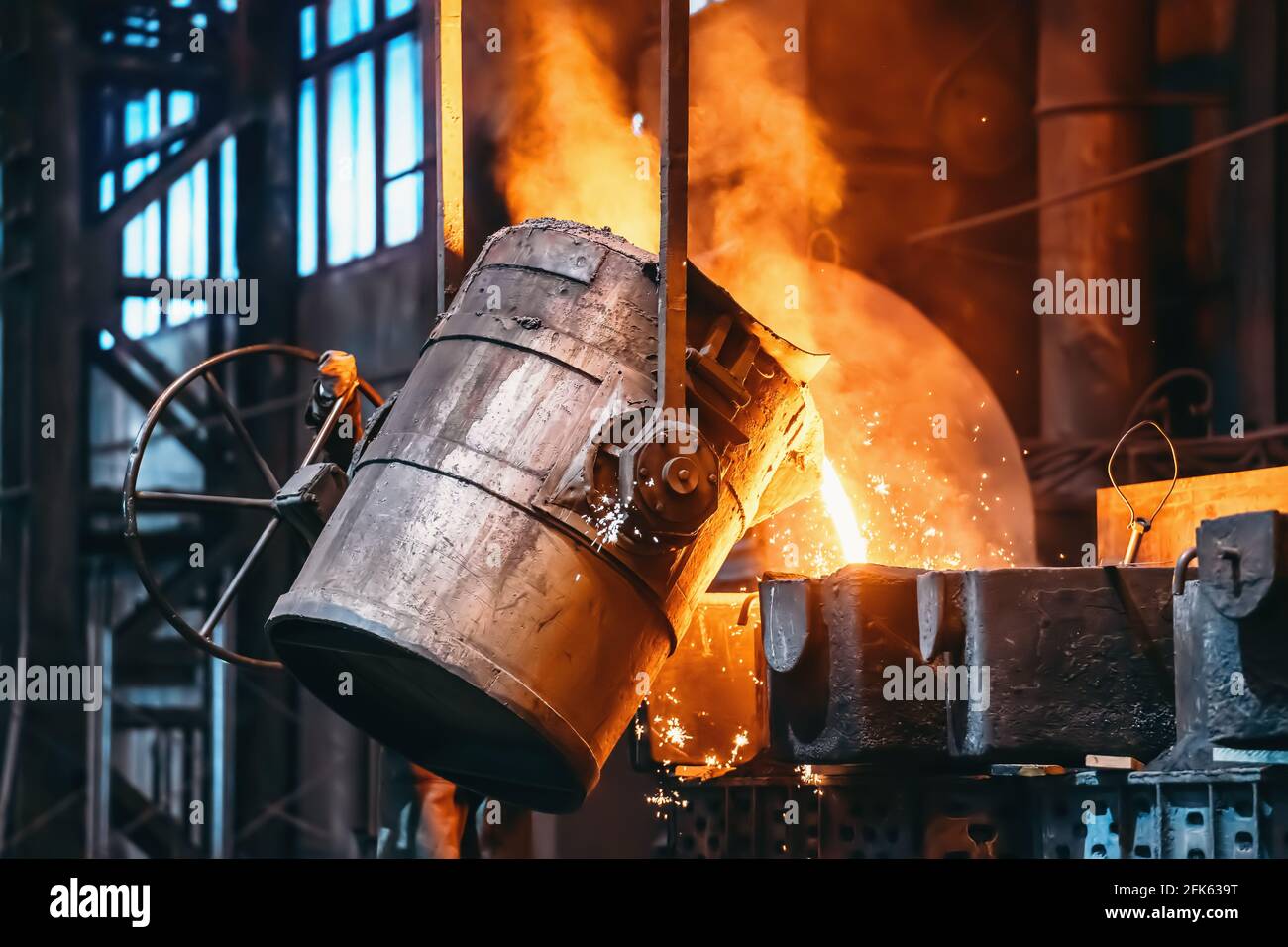

Metal casting is a classic craft that integrates virtuosity with engineering precision. From old methods to modern-day improvements, this process has actually progressed significantly. Numerous techniques, such as sand casting and lost-wax casting, display the adaptability of the medium. Meanwhile, technologies like 3D printing are reshaping exactly how shops operate. As the lines in between functionality and virtuosity blur, one have to take into consideration just how these developments impact both modern applications and conventional techniques. What lies in advance in this evolving landscape?The Principles of Metal Casting

Metal casting, an essential process in production, involves pouring molten steel right into a mold and mildew to achieve a desired form. This technique acts as a foundation in the manufacturing of complex steel components throughout numerous markets. Crucial element of steel casting include the choice of products, which can range from aluminum to steel, each chosen for its details homes and application suitability. The procedure starts with mold and mildew production, which can be made from sand, steel, or porcelains, depending on the casting method made use of. The liquified metal is then very carefully put right into the mold, where it cools and solidifies. Crucial elements such as temperature control, cooling down rate, and mold and mildew style greatly affect the end product's quality and characteristics. Additionally, recognizing the chemical and physical residential or commercial properties of the metal aids in enhancing casting efficiency, ultimately enhancing the effectiveness of the production process and ensuring premium outcome customized to particular demands.Conventional Casting Techniques

Traditional casting methods include a variety of techniques that have stood the examination of time, showing their efficiency in producing detailed steel elements. One noticeable method is sand casting, which employs a mixture of sand and a bonding agent to produce mold and mildews. The adaptability of sand casting permits the manufacturing of diverse shapes, making it ideal for both small and large-scale production. Another notable method is investment casting, commonly used for complex and accurate geometries. This technique entails developing a wax pattern that is covered in a ceramic shell, which is then heated up to remove the wax, leaving a tooth cavity for liquified metal. In addition, die casting is made use of for high-volume production, where molten steel is infused into recyclable steel molds. Each of these standard techniques stays relevant, showcasing the craftsmanship and skill inherent in the art of steel casting, while satisfying the demands of different industries.Modern Innovations in Metal Casting

As industries evolve, technologies in steel casting are improving manufacturing procedures and enhancing efficiency. Advanced technologies such as 3D printing and computer-aided style (CAD) are revolutionizing mold and mildew creation, enabling intricate designs that were previously unattainable. These approaches facilitate fast prototyping, reducing preparations and fostering imagination in product growth.Furthermore, the assimilation of automation and robotics in foundries is streamlining operations, minimizing human mistake, and increasing safety. Smart see page sensors and real-time tracking systems allow exact control of temperature level and product properties, making sure better outcomes.

Lasting techniques are arising, with the usage of energy-efficient heating systems and recycled products, minimizing environmental effect. The adoption of composite products and sophisticated alloys is additionally expanding the opportunities of steel casting, leading to more powerful and lighter parts. In general, these modern-day innovations are transforming metal casting right into a much more effective, precise, and eco accountable sector.

Applications Throughout Numerous Industries

While varied markets significantly count on steel casting, the strategy's versatility plays a crucial role in meeting specific application demands. In the automobile sector, metal casting is important for producing engine parts, transmission housings, and various other intricate parts that require accuracy and longevity. The aerospace industry take advantage of lightweight casted parts, guaranteeing both performance and gas performance. In addition, the building sector utilizes metal casting for architectural elements, such as beam of lights and sustains, improving the stability of structures and bridges.

Moreover, the energy industry employs metal casting for generator blades and other substantial machinery that must stand up to extreme problems. Medical devices also see applications of metal casting, particularly in surgical tools and prosthetics, where precision is essential - Metal Casting. Generally, the adaptability and integrity of metal casting make it important across different areas, adding to the innovation of innovation and facilities in modern culture

The Artistic Side of Metal Casting

Often linked with industrial applications, steel casting also finds its place in the domain of art, where competent craftsmens change liquified steel into elaborate designs and meaningful sculptures. This imaginative side of steel casting includes diverse methods, including sand casting, lost-wax casting, and financial investment casting, each visit the site offering special opportunities for creativity. Artists make use of these techniques to create works that vary from abstract types to realistic representations, permitting for personal expression and commentary on contemporary problems.

Frequently Asked Inquiries

What Precaution Are Important in a Metal Casting Factory?

Important precaution in a steel casting factory consist of individual protective devices, correct air flow, emergency situation procedures, training in dealing with molten steels, routine devices upkeep, and clear communication of risks to ensure employee safety and health and wellness. Aluminum Foundry.How Do Environmental Regulations Impact Metal Casting Processes?

Ecological laws significantly affect steel casting procedures by mandating using cleaner modern technologies, minimizing emissions, and promoting waste administration methods. Conformity commonly needs investments in tools, training, and Aluminum Foundry modifications to existing treatments to minimize ecological influence.What Are the Common Problems in Metal Spreadings?

Usual issues in steel castings consist of porosity, shrinkage, additions, and misruns. These issues can emerge from incorrect mold and mildew layout, poor temperature level control, or contamination, ultimately affecting the structural stability and total quality of the final product.Exactly How Is Waste Managed Throughout Metal Casting Manufacturing?

Waste administration in metal casting manufacturing entails reusing scrap steel, executing effective product usage, and making use of innovative technologies to lessen waste. Shops adopt methods like sand recovery and proper disposal approaches to decrease environmental effect.What Profession Opportunities Exist in the Metal Casting Sector?

The metal casting sector offers varied career chances, consisting of functions such as factory supervisor, metallurgical engineer, quality control examiner, pattern maker, and manufacturing manager, providing to numerous ability collections and experience in making processes.Metal casting, an essential process in production, involves pouring molten steel right into a mold to achieve a wanted shape. Furthermore, die casting is utilized for high-volume production, where molten metal is infused into recyclable metal mold and mildews. While varied sectors significantly rely on steel casting, the strategy's adaptability plays a crucial function in conference certain application needs. Frequently linked with industrial applications, metal casting likewise finds its location in the domain name of art, where experienced craftsmens transform liquified metal into expressive sculptures and complex styles. Waste management in metal casting production involves reusing scrap metal, carrying out reliable material usage, and making use of advanced technologies to decrease waste.

Report this wiki page